Welcome !

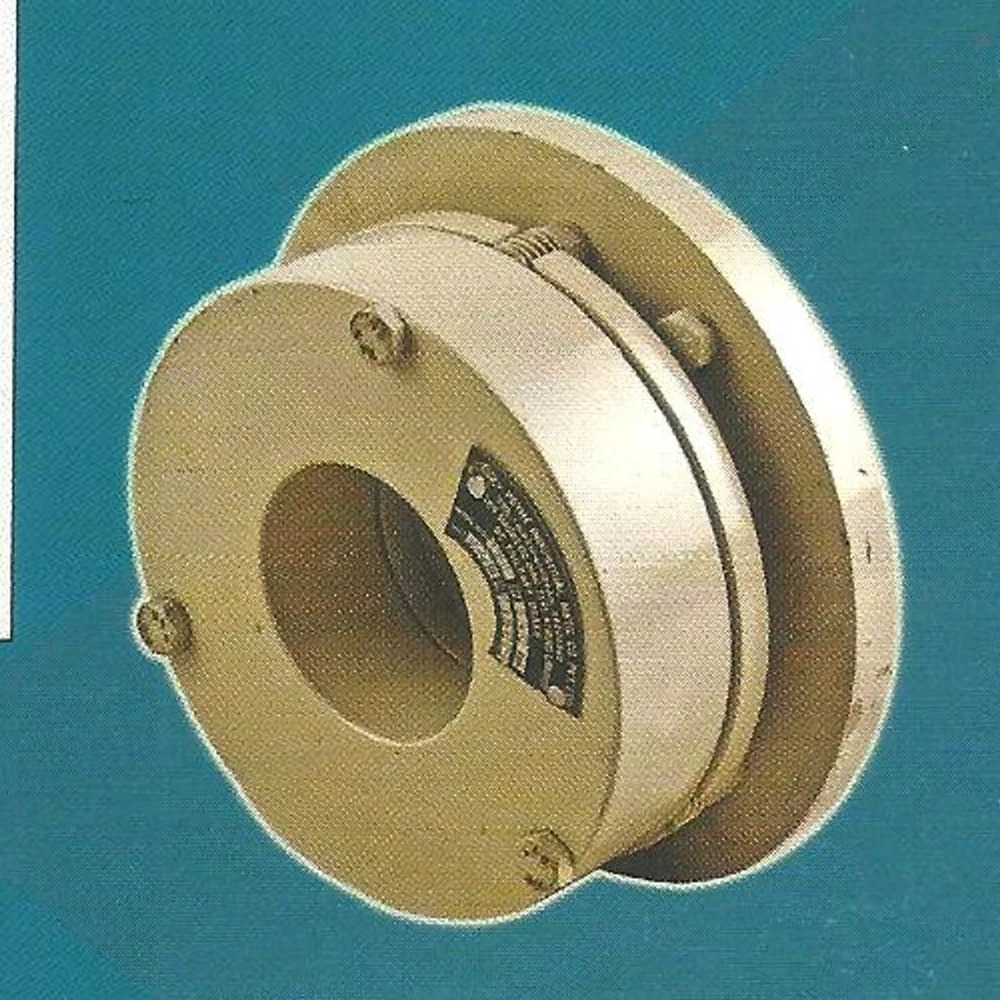

Trusted and Durable Electromagnetic Clutches, Clutches and Brakes Spares, Clutch Plates, Multiple Disc Clutches, etc.

Most Popular Product

Magna Core Clutches & Brakes Pvt. Ltd., established in 2005 and

based in Lonavala, Maharashtra, India, is a prominent manufacturer,

supplier, and exporter of high-quality clutch and brake solutions. The

company specializes in a wide range of products, including

electromagnetic clutches, clutch plates, multiple disc clutches, and

various clutches and brakes spares, catering to diverse industrial

applications.

With a strong focus on precision engineering, durability, and performance, Magna Core ensures that its products meet stringent quality standards and deliver reliable operation in demanding environments.

With a strong focus on precision engineering, durability, and performance, Magna Core ensures that its products meet stringent quality standards and deliver reliable operation in demanding environments.

Its expertise in designing and manufacturing

advanced clutch systems positions Magna Core Clutches & Brakes as a

trusted partner for industries requiring efficient mechanical power

transmission and braking solutions, combining technical excellence with

robust support services.

Quality Standards

Our range of clutches is engineered to meet international standards and is equivalent to Z.F. (West Germany), Siemens (West Germany), Stromag Matrix (England), Ortlinghaus, Romanian, and Russian types. To ensure the highest quality, we welcome third-party inspections of our clutches for global clients, conducted by reputed agencies such as the Central Machine Institute, Bangalore. From raw material inspection to finished products, our Quality Control team rigorously monitors every stage of production. Strategically located in Lonavala, between Mumbai and Pune, our facility ensures convenient transportation and timely delivery.

We continually expand and diversify our product range to meet the evolving demands of various industries. Under the guidance of our Managing Director, Mr. K. R. Damale, the company has grown rapidly, serving a wide and prestigious client base.

Our Team

Our dedicated team of professionals, including engineers and technicians, collaborates seamlessly to manufacture technologically advanced, high-performance electro-magnetic multi-disc clutches, brakes, and telescopic brushes tailored to client specifications. Experienced quality analysts perform rigorous checks on raw materials and finished products, conducting stage-wise tests to ensure efficiency and reliability. Regular in-house training keeps the workforce updated on production processes and equipment usage.

Clientele

Our client-focused approach prioritizes understanding expectations, ensuring product quality, and delivering consignments on time. This commitment has helped us establish long-term relationships with both domestic and international clients. Our workforce stays updated with industry trends, ensuring complete client satisfaction and a growing global client base.

Quality Assurance

We are committed to delivering superior quality electro-magnetic multi-disc clutches, brakes, and telescopic brushes. Our QC team monitors raw materials and manufacturing processes, testing for raw stopping power, tolerances, surface finish, pressure, and stress-related defects. Third-party inspections validate that our products meet international standards. Additionally, all products are packed as per client specifications to ensure safe transit.

Infrastructure

Our modern manufacturing unit spans 95 65 ft and houses advanced machinery, including:

Equipped with an in-house design unit using advanced CAD/CAM software, we innovate and refine product designs efficiently.

Warehousing & Packaging

Our spacious warehouse is organized into sections for easy product identification. High-quality packaging materials are used to safeguard products during transit. Situated between Mumbai and Pune, our location ensures timely deliveries nationwide. Expert delivery managers track lead times, ensuring consignments reach their destination promptly.

Quality Standards

Our range of clutches is engineered to meet international standards and is equivalent to Z.F. (West Germany), Siemens (West Germany), Stromag Matrix (England), Ortlinghaus, Romanian, and Russian types. To ensure the highest quality, we welcome third-party inspections of our clutches for global clients, conducted by reputed agencies such as the Central Machine Institute, Bangalore. From raw material inspection to finished products, our Quality Control team rigorously monitors every stage of production. Strategically located in Lonavala, between Mumbai and Pune, our facility ensures convenient transportation and timely delivery.

We continually expand and diversify our product range to meet the evolving demands of various industries. Under the guidance of our Managing Director, Mr. K. R. Damale, the company has grown rapidly, serving a wide and prestigious client base.

Our Team

Our dedicated team of professionals, including engineers and technicians, collaborates seamlessly to manufacture technologically advanced, high-performance electro-magnetic multi-disc clutches, brakes, and telescopic brushes tailored to client specifications. Experienced quality analysts perform rigorous checks on raw materials and finished products, conducting stage-wise tests to ensure efficiency and reliability. Regular in-house training keeps the workforce updated on production processes and equipment usage.

Clientele

Our client-focused approach prioritizes understanding expectations, ensuring product quality, and delivering consignments on time. This commitment has helped us establish long-term relationships with both domestic and international clients. Our workforce stays updated with industry trends, ensuring complete client satisfaction and a growing global client base.

Quality Assurance

We are committed to delivering superior quality electro-magnetic multi-disc clutches, brakes, and telescopic brushes. Our QC team monitors raw materials and manufacturing processes, testing for raw stopping power, tolerances, surface finish, pressure, and stress-related defects. Third-party inspections validate that our products meet international standards. Additionally, all products are packed as per client specifications to ensure safe transit.

Infrastructure

Our modern manufacturing unit spans 95 65 ft and houses advanced machinery, including:

- Hobbing Machines

- Lathes

- Milling Machines

- Snatting Machines

- CNC Machines

- Wide Cutting Machines

- Drilling Machines

- Grinding Machines

Equipped with an in-house design unit using advanced CAD/CAM software, we innovate and refine product designs efficiently.

Warehousing & Packaging

Our spacious warehouse is organized into sections for easy product identification. High-quality packaging materials are used to safeguard products during transit. Situated between Mumbai and Pune, our location ensures timely deliveries nationwide. Expert delivery managers track lead times, ensuring consignments reach their destination promptly.

|

MAGNA CORE CLUTCHES & BRAKES PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |